Deep Dive into Offshore Flaring and Stranded Gas

Deep-Dive into Offshore Flared and Stranded Gas

While CyaNH3

intends to develop a solution for each of the three opportunities, we are the

furthest ahead with a solution for off-shore flared and stranded gas. This page therefore focuses

on flared and stranded gas from off-shore developments.

Data is provided in a combination of Field (English

Imperial) and Metric units following regional industry conventions. For example, Field units tend to be preferred

in the Gulf of Mexico and West Africa, while Metric is the norm in Brazil.

General

As discussed earlier, the de-facto solution for gas

monetization has been the following in preferential order.

·

Collect and sell gas to local consumers, ideally

transmitted via pipe-lines.

·

If the distance to the consumer is excessive

(field and project specific but notionally a 1000 miles), consider conversion

of the gas to liquified natural gas (i.e., LNG). Currently for this solution to be economical,

typically any new project requires enough feed gas to produce roughly 5 mmtpa

of LNG (or a gas rate of about 666 mmscfd) for an extended duration (i.e. 20+

years).

Other options that were considered from the 1980s

through the early 2000s include the conversion of natural gas to a liquid (i.e.,

diesel, dimethyl ether, methanol). These

processes proved to be less economical than LNG (for large scale applications)

and eventually LNG won out as the preferred solution.

Another concept studied throughout the 2000s was

compressed natural gas (“CNG”), where the gas is compressed and stored in

bottles, high-pressure pipes or drums. The

table below presents the amount of energy stored in a cubic foot of natural gas

(typical mixture of ~ 95% methane and ~5% ethane) at different conditions

relative to LPG and Gasoline

|

|

Natural

Gas |

CNG1 |

LNG2 |

LPG |

Gasoline3 |

|

Btu /cubic foot |

1010 |

247

k |

618

k |

748

k |

~

1 million |

Notes:

1.

Assumed at typical CNG pressure of 3,600 psi

(245 bar)

2.

Assumed at typical LNG temperature of – 260oF

(-160 oC)

3.

Per Gas Processors Suppliers Data Book (GPSA)

So, while CNG has made head-way as a fuel in local-transit

solutions such as buses and taxis, where the vehicles travel short distances

and can refueled at central hubs, CNG has had little support as a transport

mechanism for large quantities of natural gas from suppliers to consumers. Purely from an energy density standpoint, LNG

is currently the preferred choice for transport of large quantities of natural

gas.

Though the work performed by Amoco in the 1990s on

natural gas to DME did not get strong support, the concept they were exploring

deserves merit. More specifically, they

were trying to promote the conversion of natural gas to a product that could be

handled as a liquid at higher temperatures and lower pressures. DME (Dimethyl Ether) has a boiling pint of

minus 11 oF, while LPG has a boiling point of minus 44 oF.

One current trend considers Hydrogen, which is

commonly perceived as the next great fuel.

True from a pure molecular standpoint, H2 is the considerably

more energy dense than the hydrocarbon fuels, but as the lightest element, it

is also least energy dense in gaseous form (324 btu /scf) and requires the

lowest temperature (minus 422 oF) to liquify; thus, H2 is

far more difficult to produce, store and transport.

As such, currently the de-facto solution remains

LNG. It, though, has its own issues

particularly for remote onshore and deep offshore.

Deep Offshore Stranded Gas

While the industry has progressed well in developing

LNG plants around the world where significant quantities of gas (5 MMTPA) are

available for extended periods (20+ years), there remain a great number of

fields offshore, where the gas cannot be collected and processed

economically.

Thus, in the2010s, the Oil & Gas industry spent

considerable effort to develop floating LNG (“FLNG”) units. The smallest of these is 0.5 MMTPA (by Golar)

but it’s limited to extremely shallow waters and where the gas is dry. The others range in size from 1.2 mmtpa

(Petronas 1 & 2) to Shell’s Prelude at 3.5 mmtpa.

There are two fundamental outstanding issues with this

solution:

·

Motion issues offshore cause process

instability: Typically, LNG consists of

Methane and some Ethane with trace amounts of LPG (depending on market). However, the gas from the reservoirs is

generally not dry (i.e., it is typically associated with LPG and NGLs). Thus, cryogenic separation is required, using

distillation columns which are susceptible to motion. Golar (Gimli FLNG) has attempted to solve

this by moving the FLNG vessel into protected shallow-waters. Shell has attempted to solve this by

increasing the size of the vessel to the point that it has limited response to

metocean conditions. It is important to

note, that after the Prelude experience, Shell does not intend to build another

FLNG of similar size (the capital cost significantly exceeded the original

budget, and the vessel has generally not performed well).

·

Motion issues limit off-loading weather

windows: There are currently two forms

of LNG off-loading solutions, Loading Arms and Loading Hoses, as seen in Figure 8 a & b. Most LNG vessels can accommodate Loading

Arms; while a few can accommodate hoses.

However, LNG loadings arms (currently) cannot operate in sea states

greater than 1.5 meters significant wave height, and loading hoses are limited

to 5 meters significant wave height.

However, there are many existing fields where such a

concept is not commercially viable. Let

us take for example, the country with the greatest number of recent deep-water

projects, Brazil.

In 2006, Brazil made a significant oil discovery in

the Tupi field (renamed to Lula in 2010 and then back to Tupi in 2020), offshore

Brazil. The FPSO installed by Petrobras

was capable of processing 100,000 barrels of Oil per day and a little over 4

mmscmd of gas per day. The challenge was

and remains that the field is in deep, harsh waters almost 200 kilometers offshore. With the gas rate so low, Petrobras could not

justify a 200+ kilometer pipeline to shore, and instead chose instead to

reinject the gas into the reservoir (referentially, a gas pipeline to transport

this gas to the nearest point onshore would likely cost around $300

million).

Since then, Petrobras and its partners have made

multiple significant discoveries in the region (seen in Figure 10),

and as they did with Tupi, have chosen to re-inject the gas.

Offshore Flare Gas

This unfortunately, is not the case for other parts of

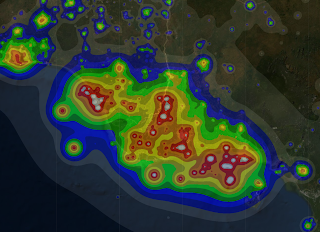

the world, examples of which are seen in Figure 11.

The figures above are satellite images of the Mexico

and Nigeria coasts with a light pollution over-lay from

A Geophysical Research Letter

The authors have obtained similar current information

for Nigeria, and we estimate the country is flaring between 400-500 mmscfd (5.2

billion cubic meters annually).

The reason these various sites are of interest is that

the gas flares are spread out over a large area, so it is not commercially

feasible to collect all the gas and justify a LNG plant

So, is there a solution for this flared /stranded gas?

We believe so.

Contact us (mail@cyanh3.com) if you have an opportunity you wish to discuss.